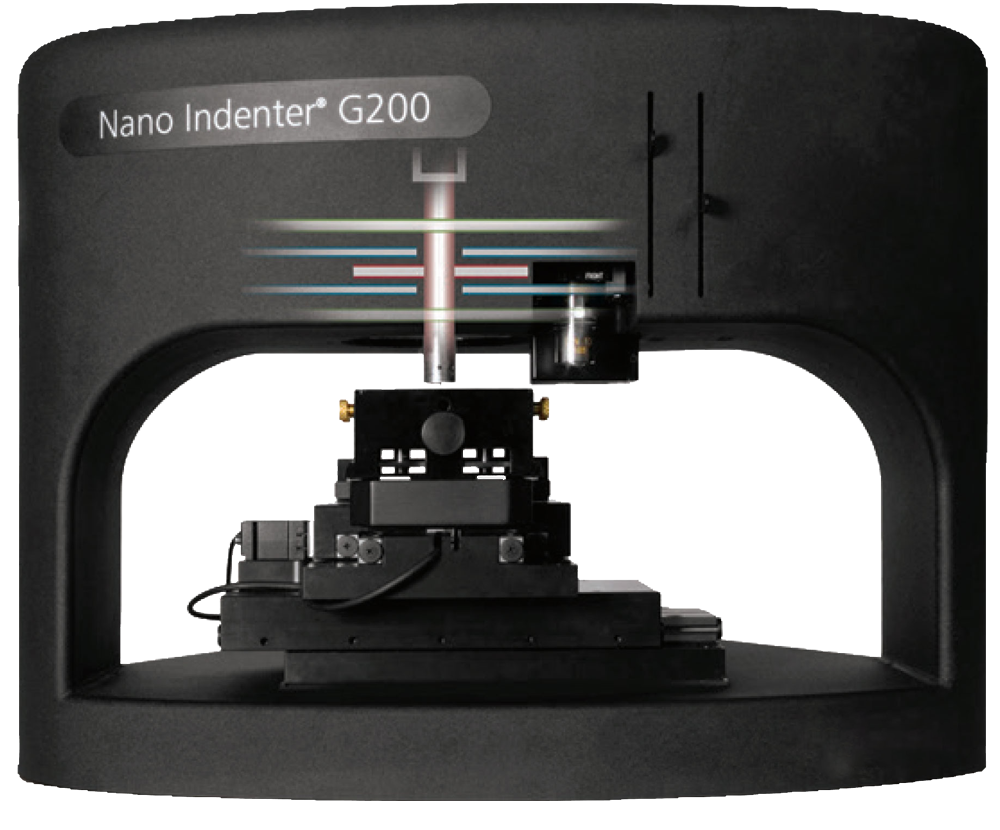

Technical specifications:

- Accurate, repeatable results compliant with ISO 14577 standard

- Electromagnetic actuation allows for unparalleled dynamic range in force and displacement

- Maximum force 10 N, with 1 mN load resolution, < 1.0 μN contact force and ~5MN/m load frame stiffness

- 500 μm maximum indentation depth and displacement resolution of 0.01nm

- Continuous Stiffness Measurement (CSM) provides an accurate measurement of the location of initial surface contact and continuous measurement of contact stiffness as a function of depth or frequency, thus eliminating the need for unloading cycles

- Standard indenter stage, 100mm x 100mm with 1 μm position accuracy

- NanoVision stage for atomic force microscopy, 100 μm x 100 μm with sub-nm positioning

- Optical microscope with 10x and 40x objective combined with 25x video screen magnification

- Configurable for routine testing or new applications

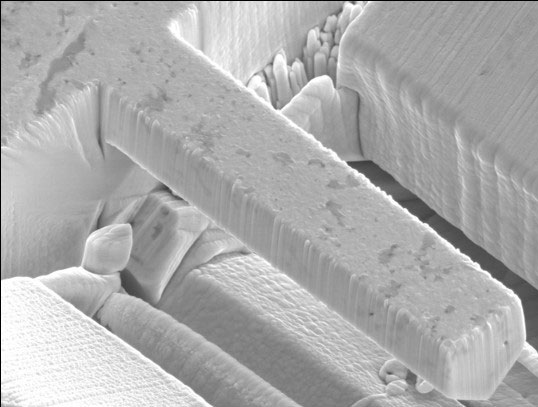

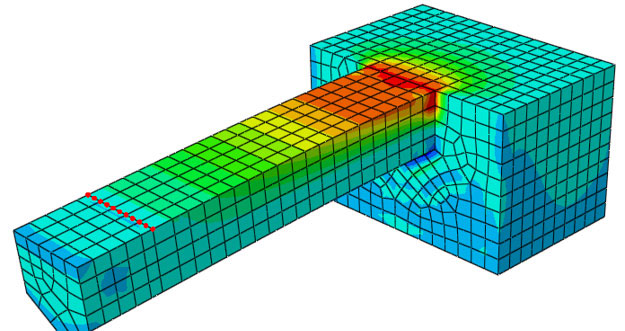

Micro-cantilever machined using the focused ion beam allows the strength and toughness of tungsten to be measured. Stress modelled using a finite element method to improve the accuracy of the interpretation of the measurement.

Image courtesy of M. Lessmann

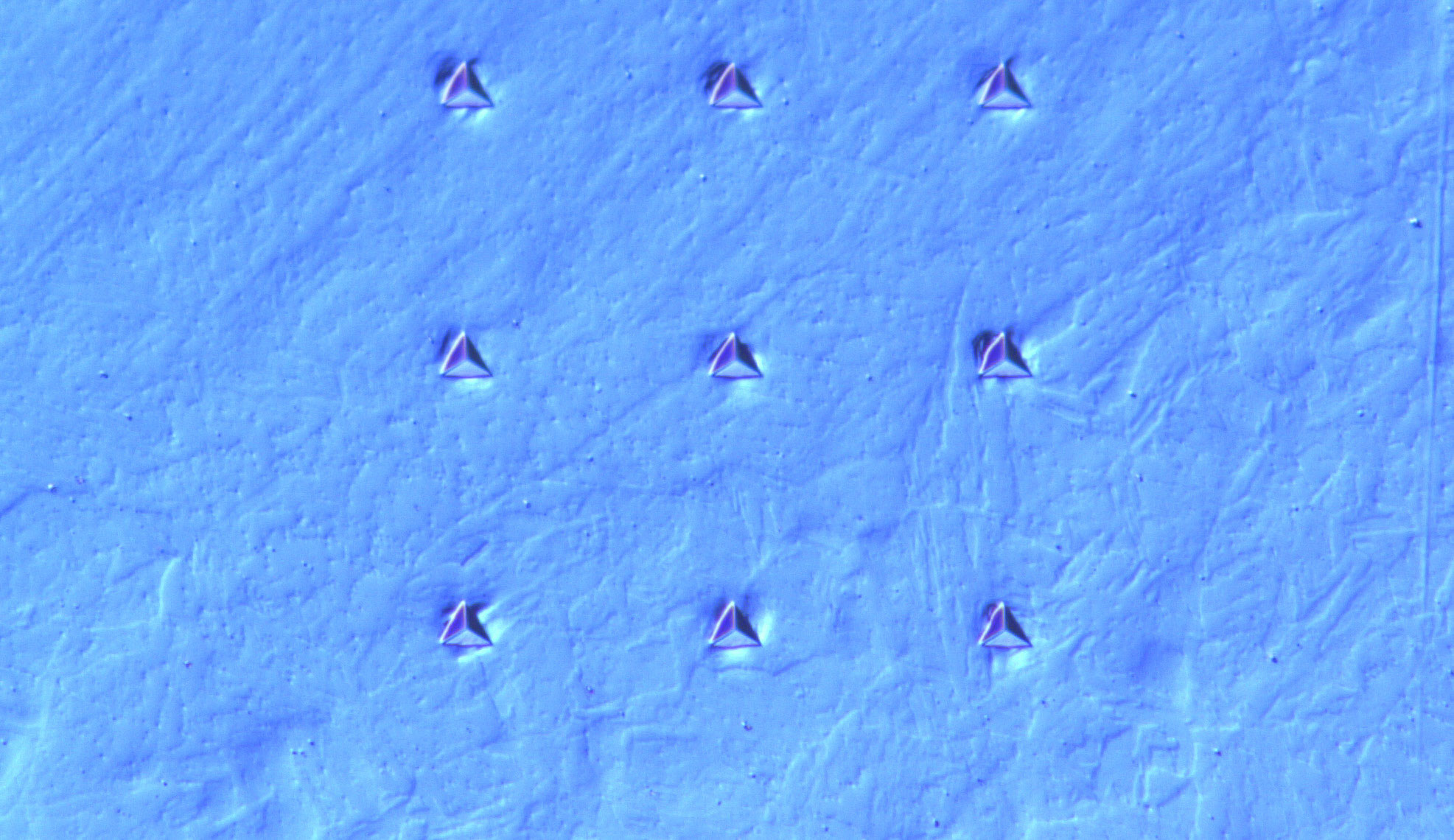

Array of indents in an ion-irradiated T91 steel viewed by optical microscopy. Indent spacing is 50 micrometres. Image by A.J. London.