UKAEA’s Materials Research Facility (MRF) prepares and examines samples of materials to assess their suitability for use in nuclear reactors. In addition to the work carried out by UKAEA, the facility can also be used by visiting researchers and academics.

We talked to Bin Zhu, who has been using MRF equipment to perform nano-indentation experiments as part of his PhD, which is jointly funded by UKAEA and the University of Surrey.

Tell us about your project and your role within it.

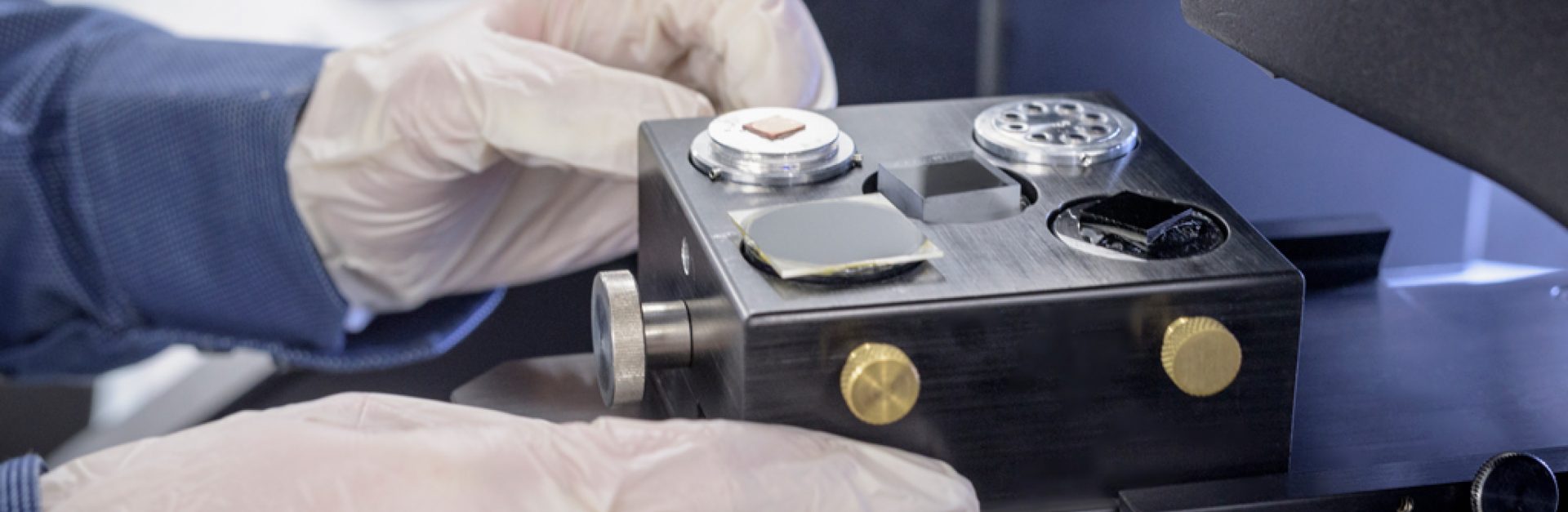

My project is about characterising and understanding microstructural, micro-hardness and micro-residual stress in laser welded Eurofer-97 steel, which could be used in a fusion plant. I’m responsible for performing the experiments, analysing data and writing papers for scientific journals.

What is the ultimate goal of the project?

The objectives are understanding (i) the residual stress at the grain level, inherited from the rapid laser welding process, and (ii) how this stress evolves at elevated temperatures.

Why is it important?

The laser welding induces high heat input and generates high residual stress. The residual stress will initialise cracks at a grain level and alter morphology, microstructure and micromechanical properties. The in-service elevated temperatures will aggravate creep relaxation cracking in the residual stress condition. Therefore, understanding residual stress plays a pivotal role in avoiding catastrophic failure regarding the structural integrity of a fusion power plant.

What do you find most interesting about the work that you’re doing?

Nanoindentation tests provide access to a lot of mechanical property information. Although it is often challenging to get an experiment to work ideally, every time it does you are rewarded with the answers to your questions. Of course, the answers usually lead to more questions, so I’m never bored in my work. Additionally, the remote control at the MRF is pretty cool.

How do you feel about being back onsite and how have you found the adjustment, given the new procedures?

The new procedures make me feel safe when I’m back onsite. Before visiting the MRF, external users learn the new rules through an induction session and report any COVID19 related symptoms online. Everyone obeys the restrictions – keeping socially distanced, wearing a mask and cleaning surfaces after touching, which reduces the risks of infection. I have found that the new procedures do not slow down the experiment process. I can still complete the setup and run experiments overnight as usual.