The Ultrasonic Fatigue Rig (UFR) measures the high-cycle-fatigue lifetime of irradiated materials, using small mm-scale specimens. A material which undergoes cyclic loading (due to mechanical or thermal stresses) will have a finite lifetime. It is important to understand how the fatigue life of materials is affected by irradiation, to ensure safe engineering design.

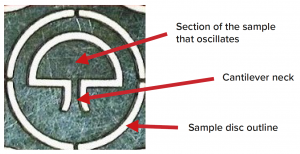

In UFR, thin foils (~200 microns) of materials have small mushroom-shaped cantilevers laser cut into them, before being irradiated to induce radiation damage. Inside the MRF hot cell, sample discs are punched from the foil into a shielded sample holder. This is mounted onto an ultrasonic transducer that applies an oscillation at 20 kHz.

The specimen geometry is chosen such that the material attached to the cantilever neck is near resonance at this frequency. The section oscillates up and down, generating a fully reversed cyclic stress in the cantilever neck. This causes a fatigue crack to initiate and grow in the region of highest stress, until the sample eventually breaks.

The deflection angle of the cantilever (i.e. the distance by which the oscillating sample moves up and down) is sampled at 200 kHz using a custom laser optics system. A finite element simulation is used to calculate the stress amplitude in the cantilever neck. By varying the ultrasonic power, a range of stress amplitudes can be produced. An S-N curve showing the fatigue lifetime as a function of stress amplitude can then be produced.

The UFR is well-suited for investigating the effect of radiation damage on fatigue resistance. The ultrasonic oscillation is fast, allowing 10 million cycles to be reached in under 9 minutes and a billion cycles to be reached in 14 hours. The small sample size reduces the activity per sample and hundreds of discs can be cut into a single irradiated foil.