Alex Cackett’s PhD project with Queen Mary University of London is based at UKAEA’s Materials Research Facility at Culham.

Her PhD is part of Strength-ABLE (Strength Achieved By Length-scale Engineering), a project funded by the European Association of National Metrology Institutes, starting in 2015.

Alex was involved in the inception of Strength-ABLE, which aims to interpret data produced from small volumes to produce engineering-relevant mechanical property data on the macro-scale.

She explains: “Once a material has been irradiated, it becomes a risk to health and safety when handled. It is therefore desirable to use small-scale testing techniques to probe their mechanical properties, since only tiny amounts of the irradiated materials are required.

“The Materials Research Facility is developing capabilities to reduce the sample sizes required to produce valuable mechanical property data. This enables research on highly irradiated materials without breaching radioactive inventory limits imposed on a non-nuclear licensed site such as Culham.

“However, the results from such small tests are not representative of large-scale material behaviour as they are influenced by a ‘size effect’ – a phenomenon whereby the smaller the test piece or microstructural length-scales, the stronger it appears.”

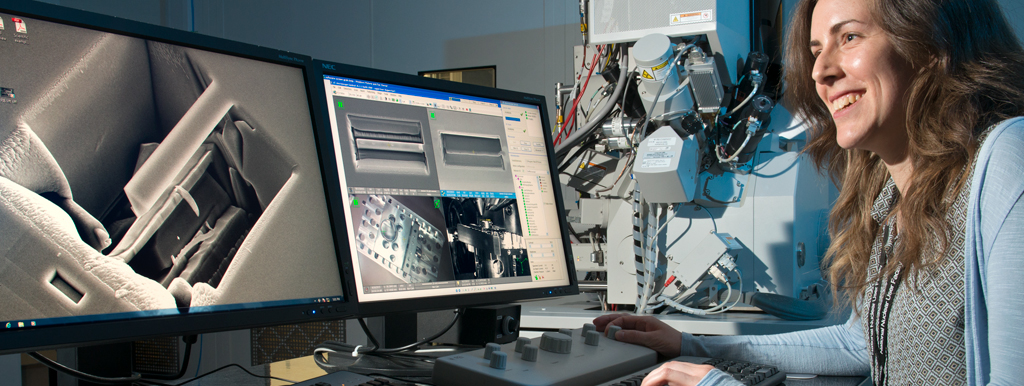

The purpose of Alex’s PhD project is to investigate this size effect by measuring stress-strain properties from small volumes of material. Using the MRF’s techniques and equipment – the Scanning Electron Microscope, Focused Ion Beam and nanoindenter – she can gain a greater understanding of how mechanical behaviour varies with length-scale. She is particularly focusing on testing copper-chrome-zirconium (CuCrZr). This material is used in the JET fusion experiment in components that are exposed to the hot plasma fuel. It will also be used within the “divertor” exhaust system of the ITER experiment and is envisaged for the DEMO prototype fusion reactor.

“The end goal is to be able to take data from small-scale tests, apply a scaling algorithm that takes various size effects into account, and predict what the bulk-scale mechanical properties are,” Alex says. “It could then be possible to monitor the condition of components in fusion and fission power stations at the MRF by extracting just a tiny sample. This would avoid shutting the plant down to remove whole components. Engineers could probe the structural integrity of reactor components more regularly, over a wider range of materials and locations throughout the reactor.”