The UFR is an instrument developed at the MRF, based on an original design from the University of Oxford, that measures very high-cycle fatigue (>108 cycles). These results are obtained in far less time than in conventional fatigue testing due to cycling being performed at ultrasonic frequencies (20,000Hz). The design includes the ability to carry out experiments on radioactive test specimens. It has laser diagnostics for precise measurement of specimen amplitude and frequency, allowing for accurate S-N curves to be constructed for analysis of fatigue lifetime.

Applications:

Verified for very high cycle fatigue measurements (>108 cycles)

Technical specifications:

- Cycles specimens using ultrasonic transducer at 20,000Hz ±500Hz frequency and 10-200 micron amplitude

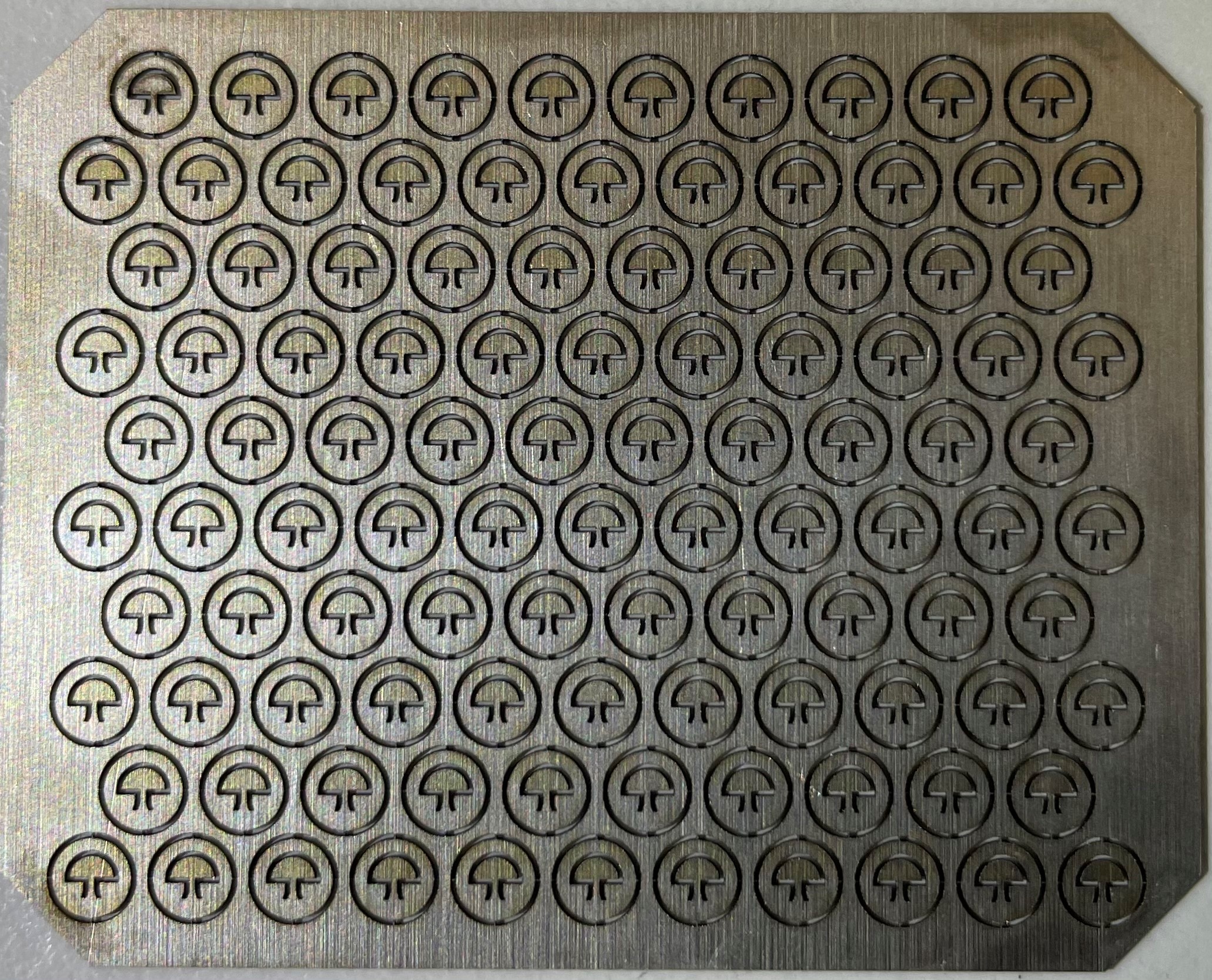

- Specimens are typically small-scaled (0.1mm) cantilevers within 3mm diameter laser cut metal foil discs. Other geometries, materials and cutting techniques may be used

- A 532nm laser, detector and optical arrangement are used to measure cantilever deflection in-situ, sampling rate 200kHz

- Advanced specimen mounting and handling techniques, developed by the MRF, allow for experimentation on radioactive materials