UKAEA’s Materials Research Facility (MRF) passed a significant milestone at the end of last year, setting it up for a successful 2020. MRF received endorsement from the UKAEA Site Safety Working Group, which means that the facility can now receive, process and experiment on irradiated samples, up to the GBq level; until recently MRF had only been able to process samples with a low level of radioactivity.

MRF was established to work with the nuclear community (fusion and fission), researchers, Universities and industry. It is part of the National Nuclear User Facility (NNUF) initiative, launched by the Government and funded by Engineering Physical Sciences Research Council (EPSRC). MRF is also a partner of the Henry Royce Institute for Advanced Materials (also funded by EPSRC), which invested in the Culham facility between 2016 and 2019.

In order to demonstrate that MRF was ready to use active samples, a number of areas needed to be reviewed.

- Sealed radioactive sources were placed into the shielded hot cells to confirm that no radiation was leaking into the surrounding environment

- The interlocks – a safety mechanism that stops the doors to the hot cell from opening if radiation is detected inside – were also checked using active samples

- Non-active materials and low-level samples were cut and prepared in the hot cells, using the remote handling systems. When compared with samples prepared by hand in MRF’s non-active labs, it was demonstrated that an equal quality of surface finish had been obtained in the hot-cell

As well as validating the hardware, operating procedures, safety instructions and emergency arrangements needed to be implemented

With this endorsement MRF now bridges the gap between Universities, who can only use samples with a very low level of radioactivity, and NNL’s nuclear licensed facilities at Sellafield.

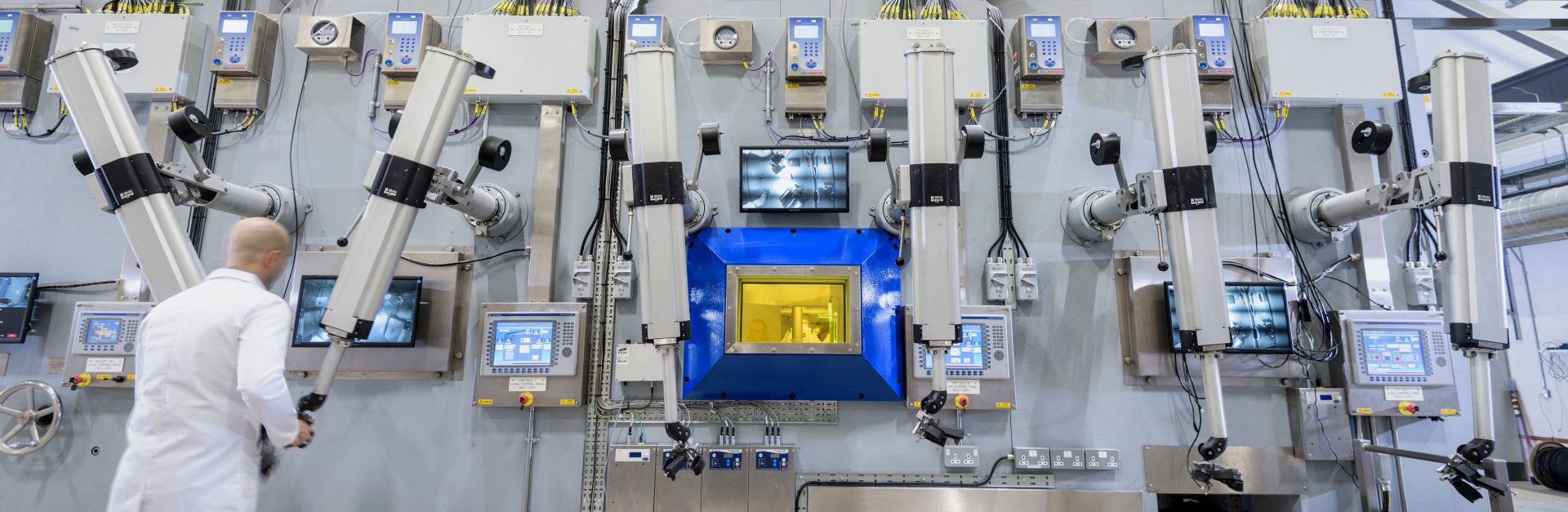

Remote handling, such as the preparation of radioactive samples where the actions of the operator are mirrored in the hot cell, is a key element of the MRF. Trolleys transport samples from the hot cells to the shielded research rooms and, once inside, robotic arms remove the samples and place them in the relevant scientific equipment. There are currently two pieces of scientific equipment fully commissioned in research rooms, with a further five expected to be ready by the end of the year.

Monica Jong, Head of Operations – MRF, said: “MRF is now in a position to realise our aim of providing organisations with the opportunity to process radioactive samples and investigate the post-irradiation properties of materials. The facility has the capabilities to conduct a range of activities, from fundamental research through to technology feasibility and development studies. This is an important step for MRF but is only the start of the planned improvements. There is a programme in place to bring additional equipment online and we will work towards being able to process TBq samples.”