APT is an analytical microscopic technique, which can recognise the position and chemical identity of the atoms making up a material, with nanometer precision.

Finding out what happens to materials on an atomic scale, in an environment subjected to irradiation, is important because of the way atoms are dislodged causing material degradation. By understanding more about this process, the hope is that more advanced materials can be manufactured, specifically finding suitable structural materials for a fusion reactor wall.

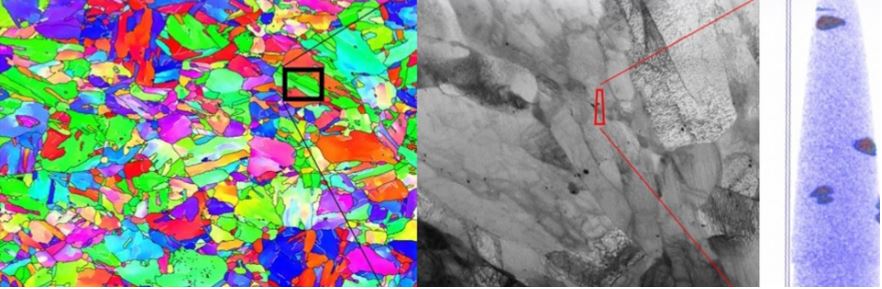

The APT method removes atoms from a needle shaped specimen by subjecting it to a high-voltage and short laser pulse. This causes field-evaporation and converts the atoms of the sample into charged ions. The applied electric field accelerates the ions towards a detector, which registers the time it takes for each ion to arrive and its impact position. From this, it is possible to determine the elements of the material, as well as the original atomic positions.

UKAEA materials scientist, Andy London, is leading work studying materials, including Eurofer steel and copper chrome zirconium, to find out more about their microstructure. Utilising the work of UKAEA’s Materials Research Facility (MRF) and Oxford University, he hopes to provide more information about the movement of different alloying elements in these materials and infer how this changes their properties.

He said: “The atom probe technique, while limited to very small samples, is an incredibly powerful material science tool. A material’s properties are determined by the identity, position and bonding of its atoms, and atom probe gives us two-thirds of this information.

“I’ve been using ion irradiation to quickly simulate neutron damage in a range of different materials. Atom probe is ideal for characterising the nanometer scale changes that occur as a result of the irradiation – which in turn affect the material’s properties at the metre-scale.

“None of the atom probe work would have been possible without the support of the Oxford Atom Probe research group; it is an amazing resource to have just a few miles from our site in Culham.”