Scientists at UKAEA’s Materials Research Facility have performed X-ray characterisation on the first ‘active’ sample in one of the facility’s Research Rooms.

The method – called X-ray Diffraction (XRD) – is a technique used by material scientists to probe the atomic structure of a material, and to give them an idea of a material’s strength. It works by irradiating a material with X-rays and then measuring the intensity and position of the X-rays that are scattered by the atoms inside the material.

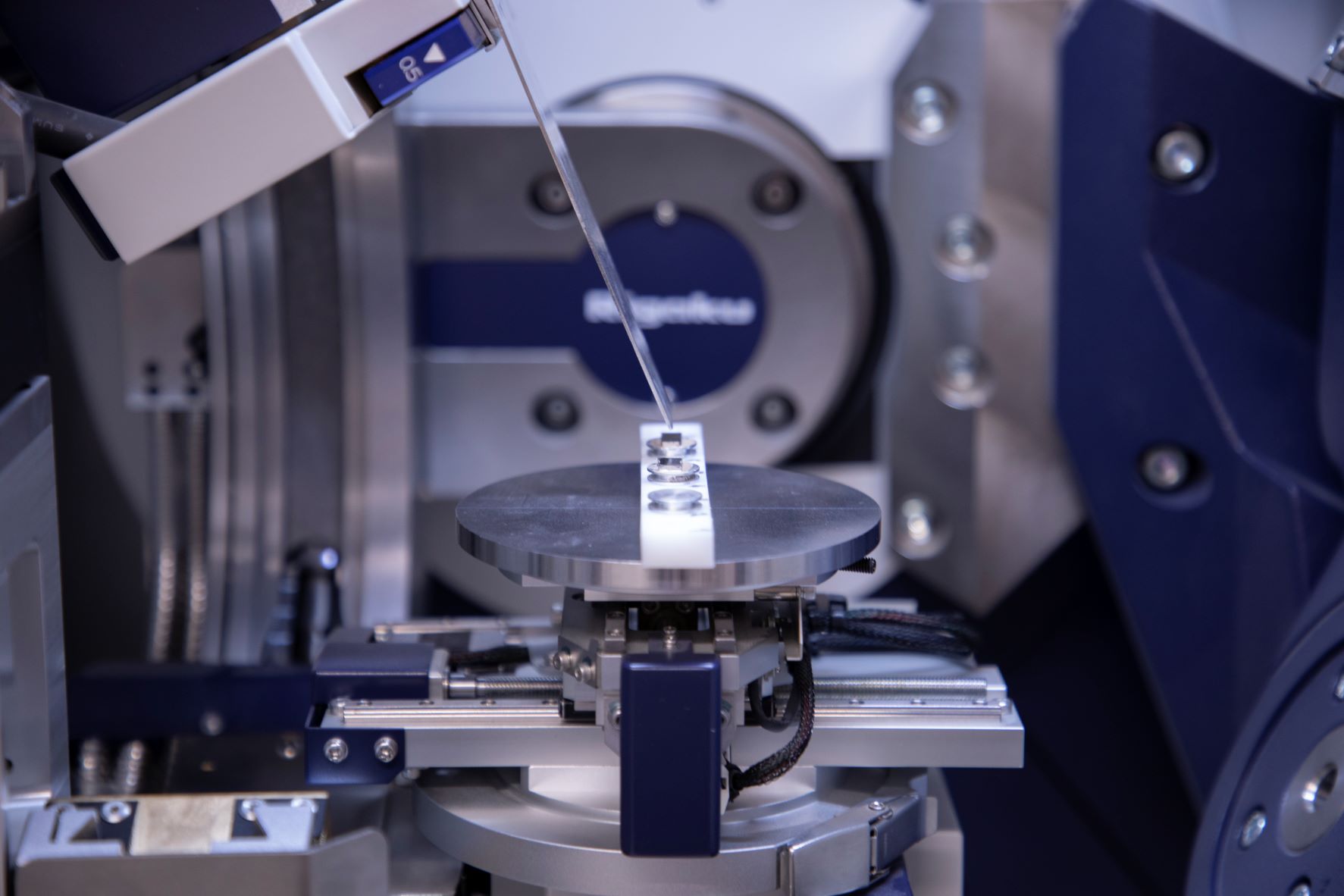

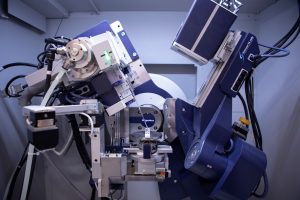

The latest tests – which were carried out on a proton-irradiated sample from the University of Manchester – used MRF’s Rigaku SmartLab X-Ray Diffractometer to characterise the structure inside the material. These irradiated samples were radioactive, necessitating testing in the safety of the MRF’s shielded research rooms.

The latest tests – which were carried out on a proton-irradiated sample from the University of Manchester – used MRF’s Rigaku SmartLab X-Ray Diffractometer to characterise the structure inside the material. These irradiated samples were radioactive, necessitating testing in the safety of the MRF’s shielded research rooms.

The measurements will help material scientists understand how components may tolerate the extreme levels of neutron bombardment in future fusion power plants.

Previously, scientists may have investigated these samples using a Transmission Electron Microscope. This was time consuming in terms of sample preparation and allows only a small part of the material to be examined in detail. With the XRD and the associated Line Profile Analysis data processing technique, scientists can measure over a wider area.

Philip Earp, an Equipment Scientist at UKAEA, said the method offers a “big-picture view” of the irradiation damage inside a material.

“The XRD offers us a complementary picture to other analysis, such as electron transmission microscopy. The latter only offers examination of a small area of the material, whereas XRD gives information from a much larger volume. It is also a non-destructive testing method and can be performed on bulk samples which are easy to prepare and handle.

“We can use this XRD equipment to look at changes which occur in materials after exposure to environments similar to those found in a fusion power plant. This information helps us to assess the suitability of the current range of candidate materials and will aid the development and selection of new materials in the future.”